Linear Alkyl Benzene

The Backbone of Modern Cleaning Solutions and Industrial Applications

Linear Alkyl Benzene (LAB) is a cornerstone of the detergent industry, playing a crucial role in the production of cleaning agents that keep our homes and workplaces spotless. Beyond its primary use in detergents, LAB has a broad range of applications in various industrial processes. This article delves into the properties, production, applications, benefits, and future prospects of LAB, highlighting its significance in modern industries.

Overview of Linear Alkyl Benzene (LAB)

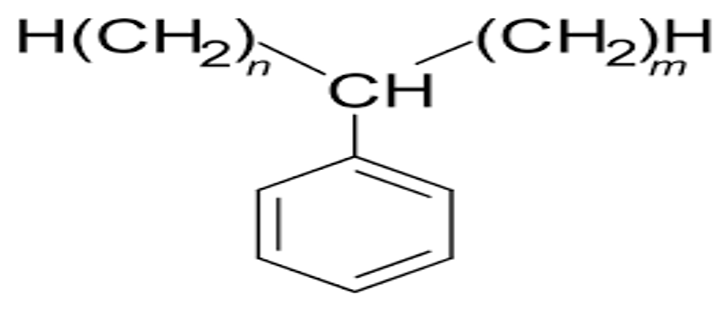

Definition and Chemical Structure

Linear Alkyl Benzene (LAB) is an organic compound consisting of a benzene ring attached to a linear alkyl chain. Its chemical formula is typically represented as C6H5CnH2n+1, where ‘n’ represents the number of carbon atoms in the alkyl chain, usually between 10 and 14. LAB is a key raw material in the production of linear alkylbenzene sulfonate (LAS), the most commonly used surfactant in detergents.

Historical Background

The commercial production of LAB began in the mid-20th century, marking a significant advancement in the detergent industry. Prior to LAB, soaps made from animal fats and vegetable oils were the primary cleaning agents. The development of LAB provided a more efficient, cost-effective, and versatile alternative, revolutionizing the cleaning products market.

Properties of LAB

Physical Properties

Appearance: Clear, colorless liquid

Density: Approximately 0.86 g/cm³

Boiling Point: Around 290-310°C

Solubility: Insoluble in water but soluble in organic solvents such as alcohols and ethers

Chemical Properties

Reactivity: LAB is relatively stable under normal conditions but can react with strong oxidizing agents.

Combustibility: It is combustible and should be handled with care to prevent fire hazards.

Production of LAB

Raw Materials

The primary raw materials for producing LAB are:

Benzene: A hydrocarbon derived from crude oil.

Paraffins: Long-chain hydrocarbons also obtained from crude oil.

Production Process

The production of LAB involves two main steps:

Alkylation: Paraffins are dehydrogenated to form olefins, which are then reacted with benzene in the presence of a catalyst such as hydrogen fluoride or solid acid catalysts.

Separation and Purification: The resultant mixture is separated and purified to obtain pure LAB.

Industrial Scale Production

Large-scale production of LAB is conducted in specialized chemical plants. Companies such as Sasol, Reliance Industries, and Petresa are major producers, utilizing advanced technologies to ensure high efficiency and product purity.

Applications of LAB

Detergent Industry

LAB is the primary ingredient in producing linear alkylbenzene sulfonate (LAS), the most widely used surfactant in household and industrial detergents. LAS is valued for its excellent cleaning properties, biodegradability, and cost-effectiveness.

Industrial Cleaners

In industrial settings, LAB-based cleaners are used for degreasing and cleaning machinery, owing to their powerful surfactant properties. These cleaners are essential for maintaining equipment and ensuring operational efficiency.

Other Applications

Agriculture: LAB is used as an emulsifier in pesticide formulations, enhancing the effectiveness of agricultural chemicals.

Textiles: It is employed in the dyeing process to improve the uniformity of color distribution—personal Care: Some personal care products include LAB for their cleaning and emulsifying properties.

Benefits of Using LAB

Efficiency in cleaning

LAB-based detergents and cleaners are highly effective at breaking down oils, grease, and other types of dirt, providing superior cleaning performance compared to traditional soaps.

Environmental Impact

LAB is biodegradable, which reduces its environmental footprint compared to other synthetic surfactants. However, proper management and disposal are necessary to minimize any potential ecological impact.

Economic Benefits

The production of LAB is cost-effective, leading to lower prices for consumers and higher profit margins for manufacturers. Its widespread availability and efficiency make it a preferred choice in the detergent industry.

Challenges and Limitations

Environmental Concerns

While LAB is biodegradable, the production process involves chemicals and emissions that need to be carefully managed to prevent environmental harm. Advances in production technology are aimed at reducing the environmental impact of LAB manufacturing.

Health and Safety Issues

Exposure to high LAB concentrations can cause skin irritation and other health issues. Proper safety measures, including personal protective equipment (PPE) and adequate ventilation, are essential during handling and production.

Innovations in LAB Production

Green Chemistry Approaches

Recent advancements focus on more sustainable production methods, including alternative raw materials and catalysts that reduce environmental impact. Green chemistry approaches aim to make LAB production more eco-friendly without compromising efficiency.

Technological Advancements

Innovations in catalyst design and process optimization have improved the efficiency and sustainability of LAB production. These advancements help in reducing waste and energy consumption, making the production process more environmentally friendly.

Future Prospects

Market Trends

The demand for LAB is expected to grow, driven by the expanding detergent market, particularly in developing regions. The increasing emphasis on hygiene and cleanliness in both domestic and industrial settings further fuels this demand.

Research and Development

Ongoing research aims to develop more efficient and environmentally friendly LAB production methods. Advances in biotechnology and green chemistry hold promise for the future, potentially leading to even more sustainable practices in LAB manufacturing.

Comparative Analysis

LAB vs. Other Detergent Ingredients

LAB is often compared with other surfactants like alpha-olefin sulfonates (AOS) and methyl ester sulfonates (MES) in terms of cost, performance, and environmental impact. LAB remains a cost-effective choice with excellent cleaning properties and biodegradability, making it a preferred ingredient in detergents.

Cost Comparison

LAB offers a balance of high performance and low production costs, making it economically advantageous for detergent manufacturers. Its cost-effectiveness ensures that consumers receive high-quality cleaning products at affordable prices.

User Guide

Safe Handling of LAB

Personal Protective Equipment (PPE): Always wear gloves and goggles when handling LAB to prevent skin and eye contact.

Ventilation: Ensure good ventilation in areas where LAB is used to avoid inhalation of vapors, which can cause respiratory irritation.

Storage Guidelines

Containers: Store LAB in tightly sealed containers to prevent contamination and evaporation.

Temperature: Keep LAB in a cool, dry place away from heat sources and direct sunlight to maintain its stability and prevent degradation.

(FAQs)

What is Linear Alkyl Benzene (LAB)?

Linear Alkyl Benzene (LAB) is an organic compound used primarily as a precursor to linear alkylbenzene sulfonate (LAS), a common surfactant in detergents and cleaning products.

What are the main uses of LAB?

The main uses of LAB include the production of detergents, industrial cleaners, agricultural chemicals, textiles, and personal care products.

How is LAB produced?

LAB is produced through the alkylation of benzene with paraffins, followed by separation and purification processes to obtain the final product.

Is LAB environmentally friendly?

LAB is biodegradable and considered environmentally friendly compared to other synthetic surfactants. However, its production process must be managed properly to minimize environmental impact.

What are the safety concerns associated with LAB?

Handling LAB requires proper safety measures as it can cause skin irritation and respiratory issues. Use of personal protective equipment (PPE) and adequate ventilation is recommended.

How does LAB compare to other detergent ingredients?

LAB is cost-effective, highly efficient in cleaning, and biodegradable, making it a preferred choice over other surfactants like alpha-olefin sulfonates (AOS) and methyl ester sulfonates (MES).

Conclusion

Summary of Key Points

Linear Alkyl Benzene (LAB) is vital in the detergent industry, offering effective cleaning properties, economic benefits, and environmental advantages. Its production and use, however, require careful management to mitigate environmental and health risks.